Propeller/Ducted Fan Design & Analysis

DARcorporation has been offering aeronautical engineering software and consulting services since 1991 and is a world class aeronautical engineering and prototype development company that boasts a team of highly skilled aeronautical engineers, software developers, project managers and prototype production personnel. Our primary objective is to help you design, prototype and test your propellers, ducted fan and open rotor systems.

DARcorporation engineers work with customers to solve their most critical problems and combine extensive engineering experience with computerized simulation tools to provide the services our customers want. Through the following disciplines, DARcorporation provides professional services for the design and analysis of propellers, ducted fan and open rotor systems.

Projects in Propeller /Ducted Fan Design

- Modular Air Vehicle Research Intelligent Kit (MAVRIK)darcorp

Aerodynamics

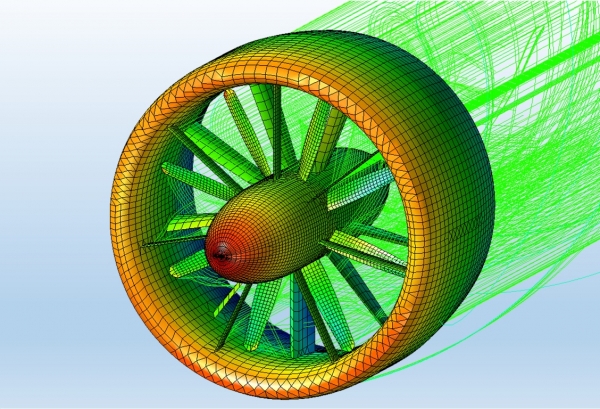

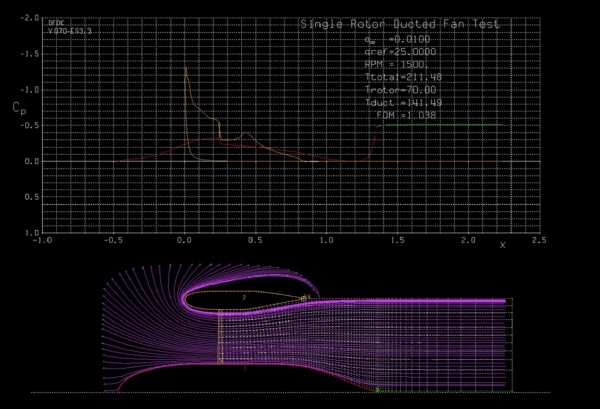

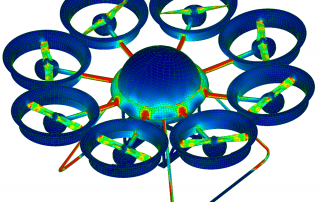

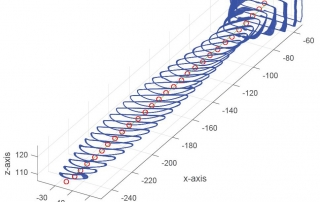

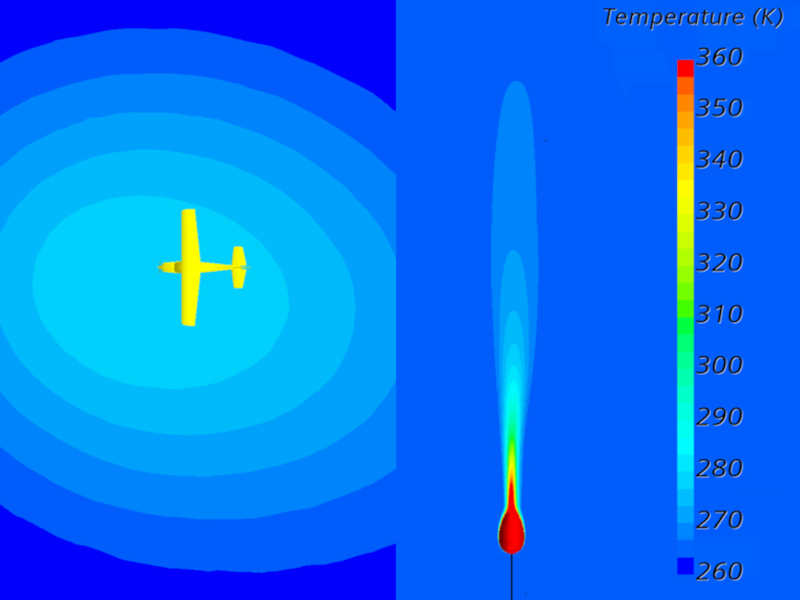

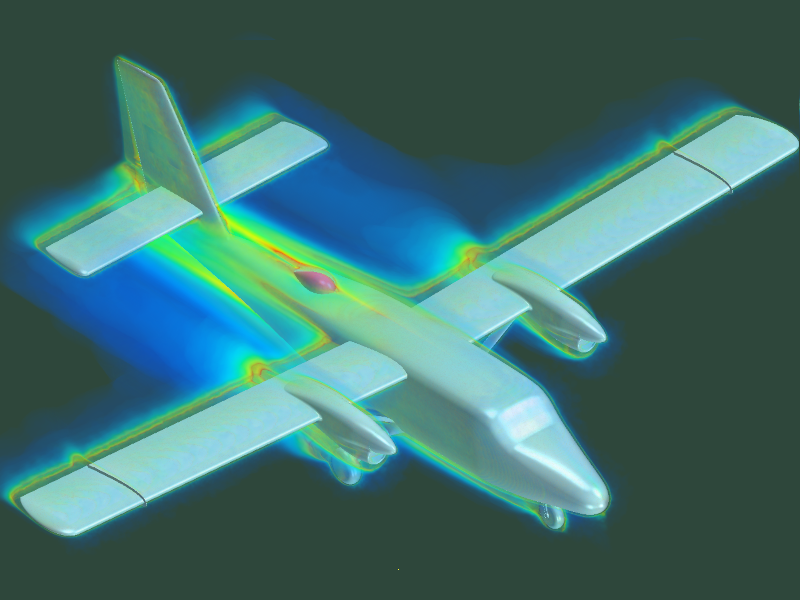

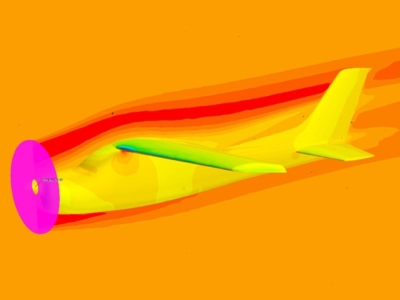

Based on Blade Element Momentum (BEM) theory, DARcorporation has developed and customized in-house software for initial aerodynamic design of propeller blades in ducted or unducted configurations. Employing a robust surface vorticity panel code and lifting line axisymmetric ducted fan analysis tool, thrust coefficient and power coefficient versus advance ratio charts are obtained. Using high-fidelity computational fluid dynamics (CFD) software with rotation simulation, the full power-thrust curve can be constructed. The deliverables of aerodynamic design include recommendations on the number of blades, airfoil selection, chord and pitch distribution, rotor diameter, RPM, etc. If a motor has not been selected based on the propeller power requirements, DARcorporation engineers have the ability to select the ideal motor for your configuration, either fuel burning or electric. Services include:

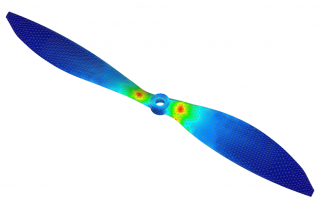

Structures

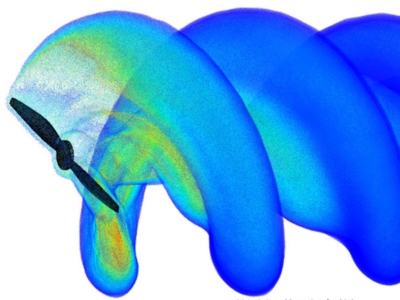

Our engineers use Finite Element Analysis (FEA) methods and software to analyze propeller/rotor and duct structures for strength, stiffness, dynamic modes, fatigue, flutter, etc. Pressure distributions, experimental or analytical, are mapped to the structural model to account for the aerodynamic loads.

Structural analysis software (Femap/Nastran, AFGROW, ZAERO, LS-DYNA, etc.) is used to model and analyze the structure, which can be made of metals (steel, aluminum, etc.), composites (glass, carbon, etc.) or any combination of metals and composites as well as bonded and fastened joints.

Results such as stresses, deformations, buckling factors, natural frequencies, flutter speeds, impact forces, etc. are compared against possible failure modes to ensure structural integrity. Unwanted vibrations are identified and designed out of the system. The propeller is designed in such a way that the natural frequencies of the blades are different from the operating RPM. The structural analysis yields material selections, material thicknesses and composite layup schedules and produces an optimized structural configuration. Services include:

Acoustics

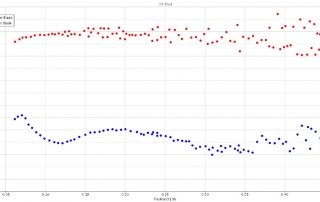

DARcorporation engineers have the capability to perform analytical and experimental analyses of propeller and ducted fan noise. Using first-order acoustic analytical tools, the noise characteristics can be obtained as a function of fan angle. The physics-based high-fidelity simulation tools we use predict the sound pressure levels at various propeller/ducted fan working conditions. With an on-site acoustic chamber and acoustic testing instruments, we can measure and compare the acoustic/noise signature of different propellers and ducted fans. These measurements allow us to help customers design/select the quietest propeller/ducted fan possible for their vehicle.

Recent Case Studies

Proposal and Rates

Please Contact Us for additional information or a detailed proposal. Your detailed proposal will include cost, calendar schedule and estimated man-hours per task. This will be provided at no cost or obligation. We look forward to hearing from you!