Design Optimization

Optimization is at the core of all design problems. Even when not formally practicing optimization, designers make choices and trade-offs about the things they design in order to create better products. There is a more automated way to go about making design choices. At DARcorporation we use several mathematical optimization techniques to systematically discover synergies and automatically seek the design which is the absolute best at its given task.

Efficiency and effectiveness are two important cornerstones at DARcorporation. These cornerstones do not only apply to the products and services we provide, but also to the way in which we work for you behind the scenes. Therefore, we invest in technology automating repetitive mathematical tasks and empowering our engineers to focus on making important, high level design decisions. In this way we have the people working on things people are good at, and computers working on things computers are good at. Mathematical optimization is an example of something a computer is very good at, so at DARcorporation we are automating this.

You can get an idea of our expertise in automatic design optimization by taking a look at the open-source tools we have published on our Github page (https://github.com/DARcorporation).

You will find:

- Python libraries for modernized versions of the famous XFOIL and XROTOR airfoil and propeller analysis codes, originally created by Mark Drela;

- An implementation of a differential evolution optimizer, capable of performing bound, constrained and unconstrained, single-objective and multi-objective optimizations on multicore and distributed computing environments;

- An airfoil optimization tool which uses the XFOIL library and the differential evolution optimizer to find minimum drag airfoils;

- A web-based graphical user interface for the airfoil optimizer, which serves as an example of our capabilities to wrap technical design codes inside a user-friendly environment.

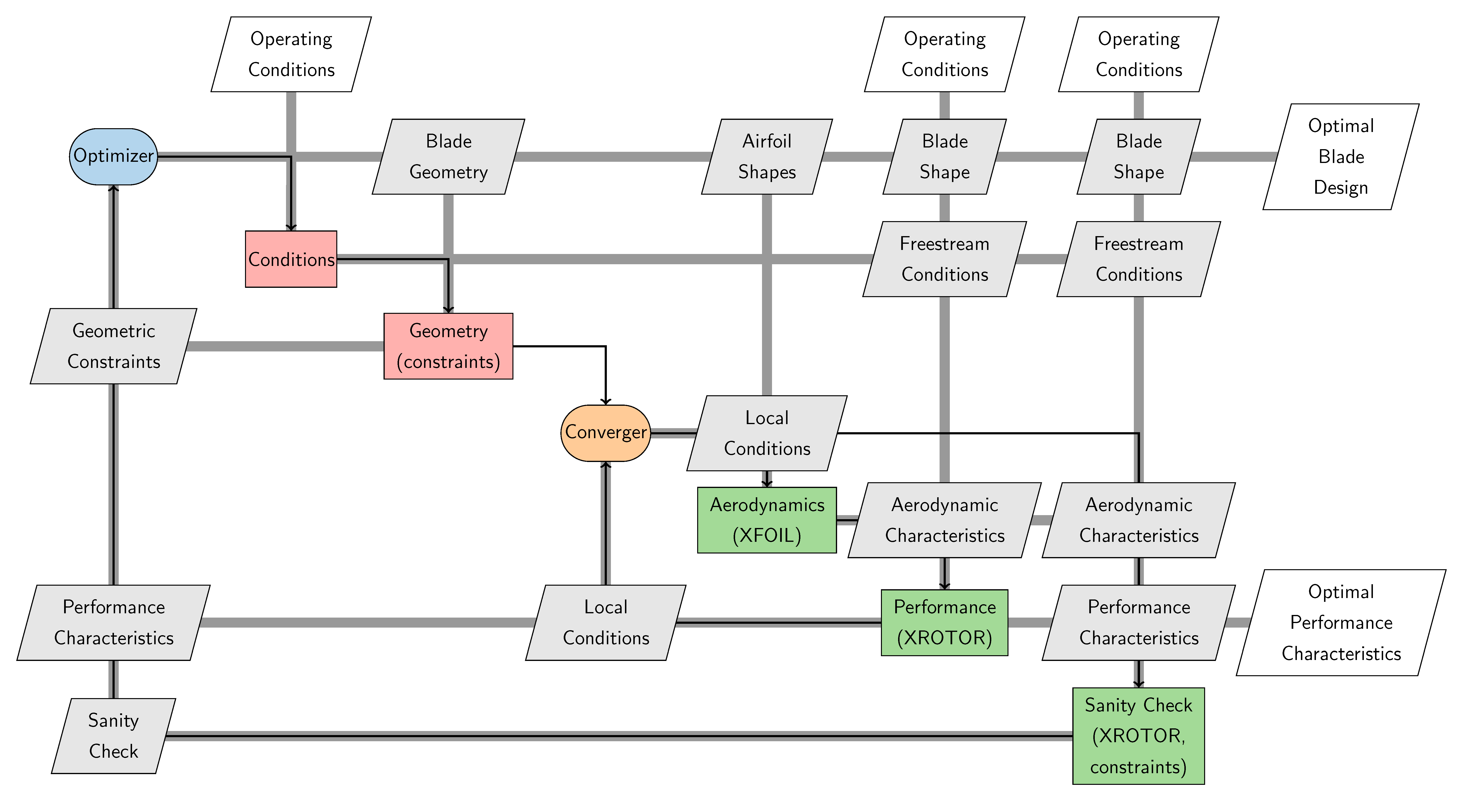

We have also developed a sophisticated in-house automatic propeller design optimization framework called PDOT (Propeller Design Optimization Tool). We are using this frame work to design propellers from scratch and overnight: completely automatically. The framework needs a very minimal set of input parameters to get started on a design, such as the required thrust and outer dimensions. The optimization exploits multicore processing environments to evaluate tens of thousands of designs and systematically identifies the blade shape with the smallest possible power consumption and minimal weight.

The PDOT framework is shown below.

We can then 3D-print the resulting designs in-house and test them on our propeller performance test stands. The figure below shows such a 3D printed propeller, which was designed solely by PDOT.

DARcorporation tools are based on state-of-the-art research and we are constantly updating and expanding our capabilities. If you have a design project, you can rest assured that our engineers, with our highly advanced design tools, will find the best possible design for the job.

Proposal and Rates

Please Contact Us for additional information or a detailed proposal. Your detailed proposal will include cost, calendar schedule and estimated man-hours per task. This will be provided at no cost or obligation. We look forward to hearing from you!