Project Description

Hi-Q Horizontal Axis Wind Turbine

Prototype Design, Analysis, Fabrication & Testing

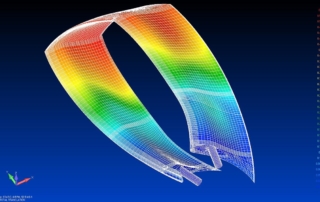

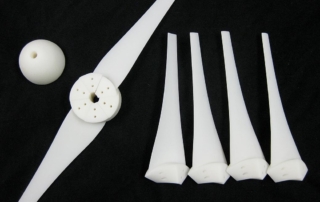

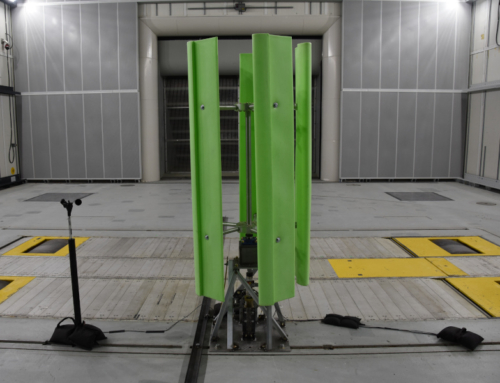

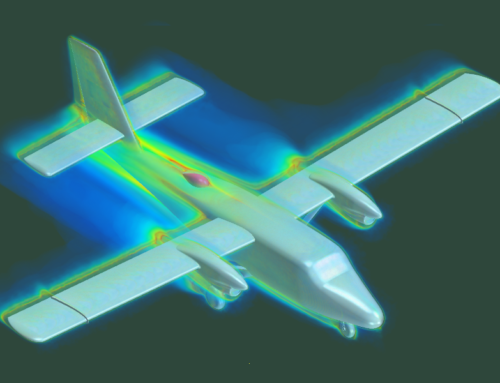

DARcorporation was involved in the aerodynamic design, structural design and prototype testing of the Hi-Q wind turbine which is an unconventional horizontal axis wind turbine. Blade Element Momentum (BEM) methods were adopted to analyze the design, methods were programmed and an in-house code was developed to analyze the performance of the wind turbine. A series of case studies was conducted with varying geometric parameters of the wind turbine. The performance in each case was carefully studied and the turbine design was optimized. Computational Fluid Dynamics (CFD) cases were simulated to verify the BEM code developed. There was good correlation between the results of the BEM code and CFD. Separate CFD cases were analyzed to extract the loads acting on the blades. These loads were used in the structural analysis of the blades. Finite Element models were created in Femap to analyze the wind turbine blades. NEi Nastran was used to analyze the models. Layup schedules for the composite blades were determined based on the loads extracted from the CFD simulations. The wind turbine blades were fabricated, using carbon fiber layup schedules based on the Finite Element analysis.